Table of Contents

Definition / general | Essential features | Terminology | Barcode and RFID technologies | Barcode and RFID scanning data applications in surgical pathology | Potential barriers and limitations | Additional references | Board review style question #1 | Board review style answer #1 | Board review style question #2 | Board review style answer #2Cite this page: Absar SF, Prichard JW. Barcoding and tracking. PathologyOutlines.com website. https://www.pathologyoutlines.com/topic/informaticsbarcodingtracking.html. Accessed March 31st, 2025.

Definition / general

- Barcoding and tracking systems allow surgical pathology practices to be supported by computer readable information

- To achieve maximal laboratory efficiency, they standardize and automate work processes by encoding identification of specimen parts at accession, grossing, histology and pathology sign out areas

- Scanning ensures patient safety by reducing laboratory errors, increasing efficiency and allowing for quality management

- Main technologies involve barcode and radio frequency identification (RFID)

Essential features

- 2 main technologies for scanning and tracking in surgical pathology are barcode and radio frequency identification

- These allow for surgical pathology practices to be supported by computer readable information for laboratories to be efficient, standardized and automated

- Barcodes exist as linear 1 dimensional barcode lines and matrix 2 dimensional barcode dot matrices

- RFID tags can be passive (no internal power source) or active (battery powered)

Terminology

- 1D barcode = linear code

- 2D barcode = data matrix code = QR code

- Radio frequency identification (RFID)

- Laboratory information system (LIS) / laboratory management system (LMS)

- Quality assurance (QA) / quality control (QC)

Barcode and RFID technologies

- Barcodes (Am J Clin Pathol 2009;131:468, Surg Pathol Clin 2015;8:123)

- More accurately read information from small labels than human eye for fewer identification errors

- Can employ quality controls of checksums or check digits and internal control lines to ensure barcode is intact and read correctly or scan fails

- Can scan multiple slide and block labels at a time

- Linear 1D barcode lines: limited information in larger space

- Matrix 2D barcode dot matrix: more information in smaller space

- Hardware

- Scanners

- Each barcode reader is connected to an individual computer at

- Accessioning

- Grossing stations

- Tissue processors

- Microtomy

- Staining

- Slide assembly

- Slide distribution

- Pathologist workstations

- Requires adequate computers and network bandwidth to support laboratory operations

- Includes

- Contact wands

- Laser barcode scanners

- Image based (camera) barcode readers

- Can be wired, wireless or fixed / mounted

- Are preferably omnidirectional, as they read symbologies in any orientation

- Each barcode reader is connected to an individual computer at

- Printers are essential for labeling specimen containers, cassettes and slides

- Labels include barcodes and other patient identification information (case accession number, patient name, slide number, etc.)

- Print on an adhesive label or directly onto the cassette or slide

- Printing technology includes impact (dot matrix) and nonimpact (ink jet, laser and thermal) printing

- Scanners

- Implementation involves

- Planning for which specimens need tracking and what the data will be used for

- Selecting appropriate label

- Determining the space available for hardware

- Developing a plan for IT downtime

- Assessing degree of IT support and finances

- Choosing a vendor whose software maintains interoperability with the laboratory's existing LIS, instruments and computers

- RFID (atlasRFIDstore: Active RFID vs. Passive RFID - What's the Difference? [Accessed 29 June 2021])

- Passive RFID

- Uses tags with no internal power source; instead, these tags are energized by the electromagnetic energy transmitted from an RFID reader

- Used for applications such as access control, specimen tracking, supply chain management and more

- Has lower price point per tag than active RFID tags

- Active RFID

- Uses battery powered RFID tags that broadcast their own signal

- Commonly used as beacons to accurately track the real time location of assets

- Provide much longer read range than passive tags

- Passive RFID

Barcode and RFID scanning data applications in surgical pathology

- Barcode or RFID on badges facilitates identification and login of staff to access rooms, equipment and software

- Barcoded paper requisitions can be scanned to file into document imaging systems

- During case accessioning, scanned requisitions and containers are positively identified and matched to the correct patients in the LIS

- Verification of relationship of requisitions to specimens, blocks and slides

- For accurate and safe handling and transfer between workflow steps

- To prevent mislabeled components and tissues

- Scanning requisitions or specimen containers at grossing bench can trigger tissue cassette engraver labeling on demand

- Only blocks labeled for the specimen being grossed are available

- Only blocks labeled for the specimen being grossed are available

- Scanning cassettes into tissue processing racks records

- Date and time a workflow step occurs

- Grossing staff

- Grossing station location

- Time that the fresh specimen tissue was placed in formalin

- Grouping cassettes in the racks for tracking through tissue processing

- Tissue processors and racks can be barcoded to

- Identify groups of blocks

- Specify which processor and which protocol is associated with each tissue block

- Determine appropriate handling of tissue for ancillary tests with special requirements

- Barcoding at embedding can

- Display gross description of tissue count, color and sizes

- Display gross images

- Track work unit processing

- Verify completeness of sets of slides for each case at case assembly before delivery to pathologists

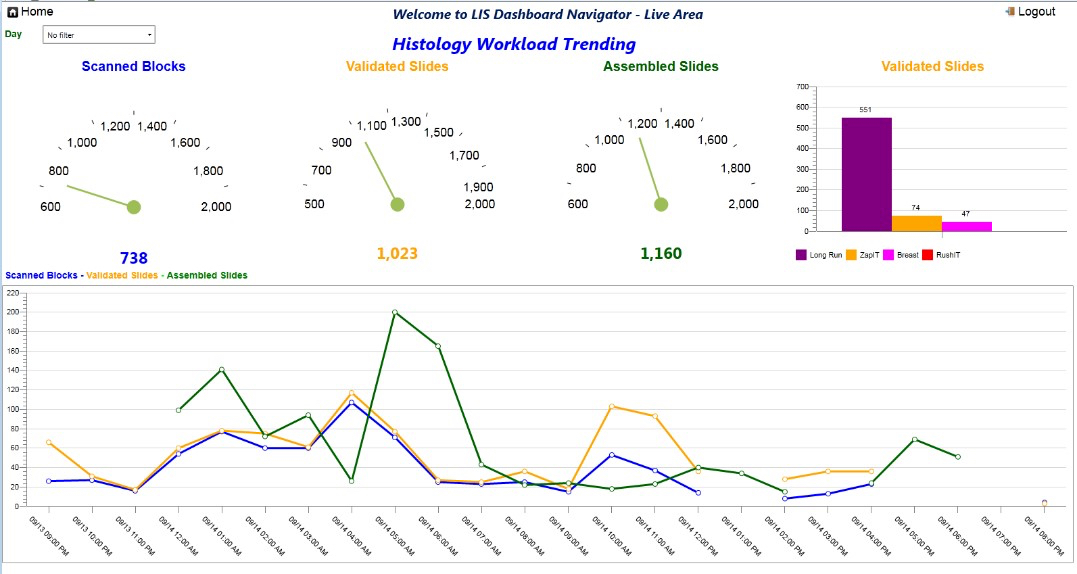

- Record metrics of units worked when requisitions, specimens, blocks and slides are scanned at specific workstations under specific staff logins

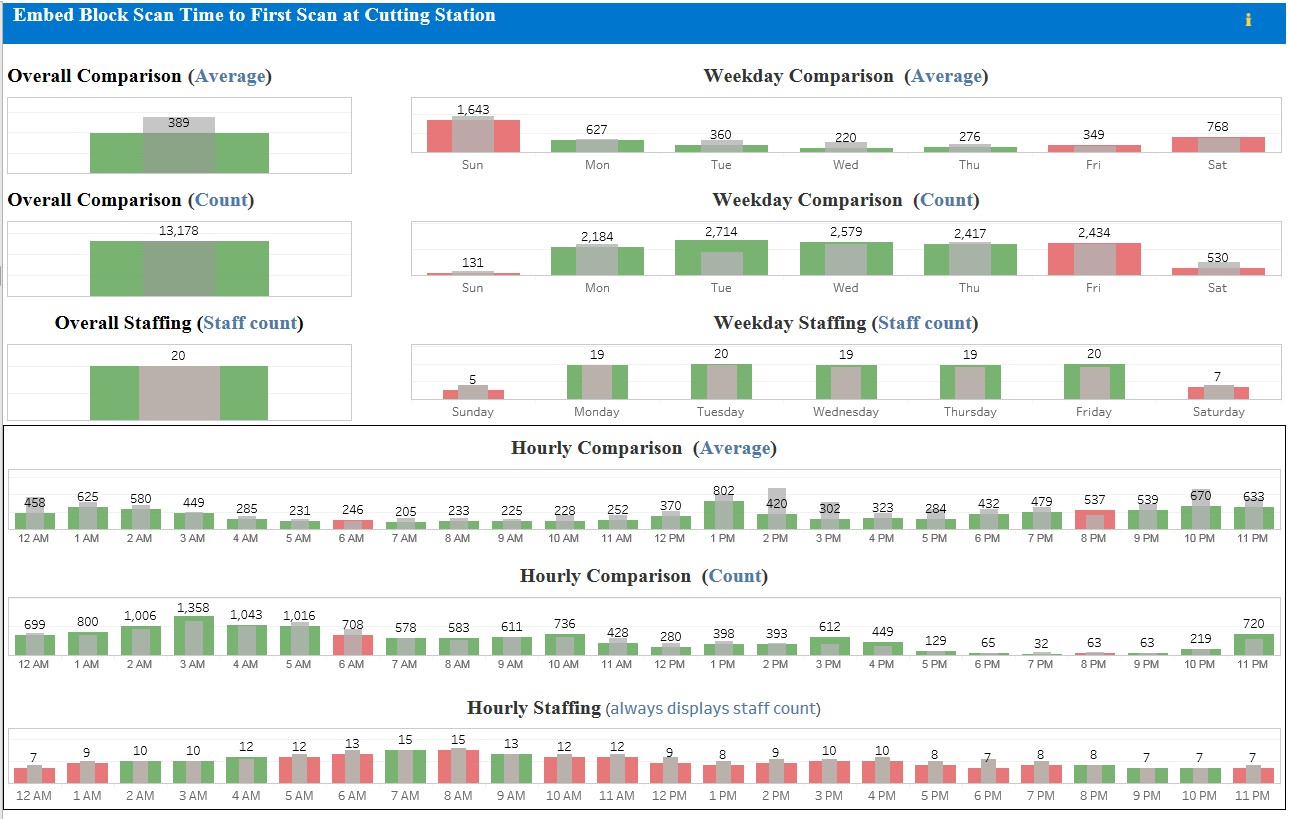

- Monitor and trend time between work steps (takt time in Lean language)

- Tablets or wall mounted monitors can facilitate visual presentation of work being done in any work area

- As graphs of barcode or RFID scans

- Visible to all staff

- Available during walkthrough by management

- Remotely accessible

- As graphs of barcode or RFID scans

- Track location for storage, retrieval and purging of specimens, blocks and slides

- Automate identification of slides for

- Assignment to pathologist

- Whole slide imaging and analysis

- Scanning a tag to open a case rather than manually typing can assure synchrony between the scanned object and the LIS context

- Reference: Clin Lab Med 2008;28:207

Potential barriers and limitations

- Cost consideration for low volume practices

- Implementation requirements include workflow process development and modification, training, education and testing

- IT expertise for initial implementation and support

- Interoperability of the instrumentation within the AP laboratory and with the other laboratories in the same institution

- Operator error, for example, tissue mixup during grossing or embedding or slide labeling error

- Mechanical delays from poor quality label printing and label printer maintenance issues

- References: Clin Biochem 2012;45:988, Diagnostics (Basel) 2021;11:2167

Additional references

Board review style question #1

Board review style answer #1

Board review style question #2

Which of the following is true about the use of RFID scanning in surgical pathology?

- Passive RFID tags are commonly used as beacons to accurately track the real time location of assets

- Passive RFID tags are more expensive than active ones

- Passive RFID tags are used for applications such as access control, specimen tracking and supply chain management

- Passive RFID tags use battery powered RFID tags that broadcast their own signal

Board review style answer #2

C. Passive RFID tags are used for applications such as access control, specimen tracking and supply chain management

Comment Here

Reference: Barcoding and tracking

Comment Here

Reference: Barcoding and tracking